Sustainability of the supply chain

Supply chain management solutions

Supply chain management solutions

While we continue to provide core sourcing services, we have expanded beyond the typical function of a sourcing agency by developing collaborative digital platforms for all of our supply chain partners, linking clients and suppliers like never before. Our objective is to help companies and merchants build items that their customers want. We are building the supply chains of the future by offering a spectrum of digital technologies that enable speed, innovation, and profitability.

Onshore retail

Our onshore wholesale company has teams throughout the Americas, Europe, and Asia and covers a wide range of products such as ladies', men's, and children's apparel, home and hard goods, promotional things, pyrotechnics, and seasonal celebration items. The commitment to creativity, innovation, and design is shared by all of our product teams.

Supply Chain Management

Our supply chain solutions are all about assisting our customers by increasing the speed and efficiency of their global supply chains, as well as enabling margin enhancement and innovation. Breaking the mould of a traditional sourcing agent, we provide mills, factories, and other vendors with a variety of solutions to help them negotiate supply chain complexity and greater compliance in order to speed the establishment of sustainable supply chain solutions. The trend engine draws inspiration from the industry's leading trends, offering firms the creative freedom to build items on time to ride the trend wave. Global collaboration is a virtual workspace where retail teams may interact remotely and use all of the resources for creating end-to-end 3D products, including as materials libraries, blocks, and patterns. Our partners can move fast from proof of concept to testing and final design thanks to virtual 3D design. Not only is the time for sample and adoption reduced from weeks to hours, but the digital assets are reusable, allowing designs to move immediately to marketing or ecommerce sites and be utilised for costing and future design. The incremental cost of product development iterations is near nil, and waste from unneeded samples and shipping is minimised. We can collaborate with thousands of vendors as partners through our Vendor Platform, assuring the optimal fit for any project in any capacity through our networks. We use dynamic costing techniques to enable commercially-led merchandising, which connects design decisions to business goals. Scenario-based analysis, forecasting, and pre-costing with real-time modifications are assisting in bringing about speed, enabling for quicker decisions and matching orders with the appropriate manufacturer. We are also working on an improved capacity management tool to better production flow with factories, allowing our vendors to benefit from higher operational efficiency and productivity, as well as improved digital communication with Global Clubs. Trade credit services, vendor compliance and sustainability, vendor supply chain services, manufacturing excellence, and smart factory solutions are some of the other solutions available to vendors and suppliers. More information can be found in our Supplier section. With a history of excellent supplier connections, our manufacturing Platform, which includes a digital order tracking system and quality resource optimisation tools, keeps us better linked with our numerous suppliers in over 40 manufacturing markets across the world. With boots on the ground, we can deliver our customers specialist and immediate knowledge while also working in real-time with vendors and factories, resulting in fewer layers and faster decisions. All of the tools on our four platforms are collaborative and may be tailored to each individual consumer.

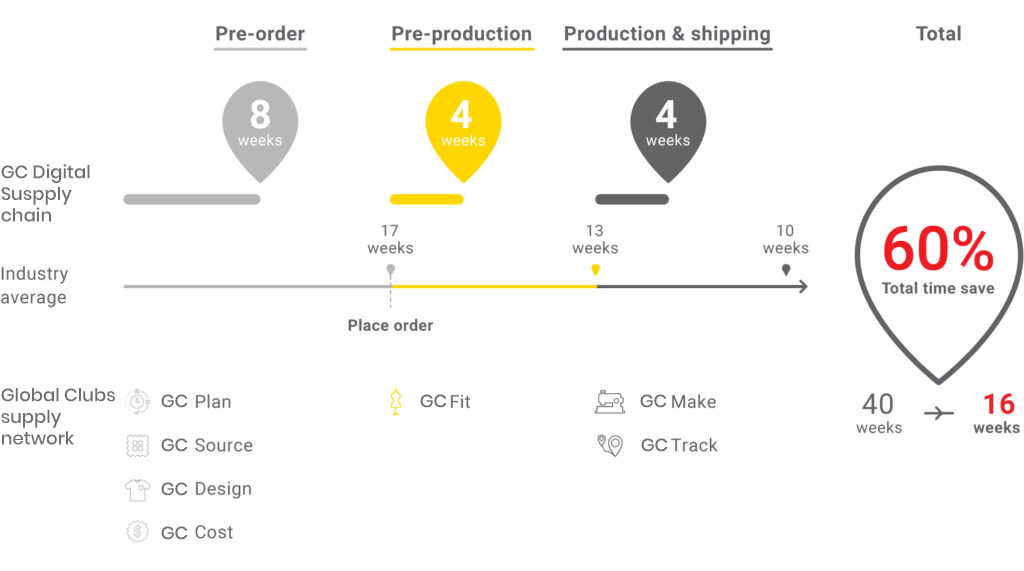

Allowing for speed

With some of retail's most significant achievements built on quickness, speed is a vital component of our strategy. Our goal is to accelerate like never before, assisting our customers in reducing production lead times and increasing speed-to-market. This entails making decisions closer to market time, responding quickly to trends, improving inventory control, and lowering markdowns - all with the goal of increasing profitability. See how we are working to enable a faster product cycle, as indicated here, by reducing the industry norm of many months to a few weeks.